Today’s Music: John Fogerty – Deja Vu All Over Again

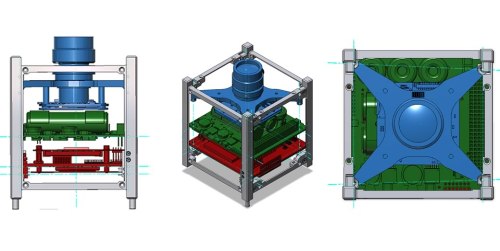

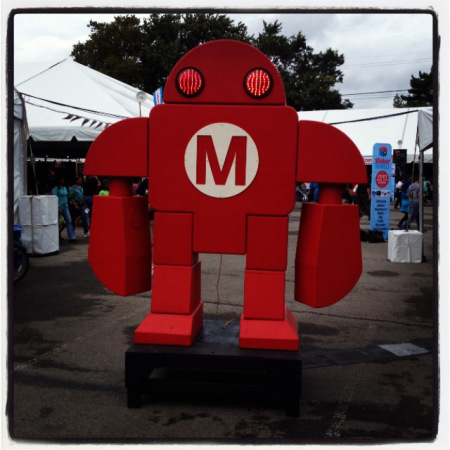

I went to the Maker Faire in NYC this past weekend. It’s a gathering of high tech do-it-yourself-ers. There were some impressive displays, including the makers of a space camera, about 5 kg, and small enough to sit in the palm of your hand.

It has a 3 mega-pixel camera, and is maneuvered with low power ion engines. It has multiple redundant computer chips to verify and error check every piece of data the device generates. By using the images from multiple low resolution (thus cheaper) devices, it can generate a composite 3D image.

It was actually brilliant in its simplicity.

On the other end, there was a series of power tools. All of these were computer controlled, and the interface was a WYSWIG What You See Is What You Get.

There is a computer loaded with CAD type software. Either 2 or 3 dimensional images can be created or imported. The software takes the image and sends it to the router.

In the example I saw, a maze was carved into a dowel, about the thickness of a broom handle.

Fantastic!

And yet…

Here’s the thing that bothered me: it was too easy.

The image was drawn on a sheet, like MS paint. The software converted it, wrapping it around to match the topology of the dowel. The user entered a depth measurement for how deep the router bit would would carve, and hit enter.

The software guided the bit to make the grooves. It went back and forth and side to side, making the channel as wide, long and deep as the user had entered.

Look what I made!

No, I have no idea how.

There were also makerbots. These machines are 3D printers. Enter a 3D image into the software (it can be one you’ve made, or one that was downloaded) and the printer will squirt out bits of plastic to build, layer by layer, whatever the image is.

Crafting like that used to be the bailiwick of skilled trained craftsmen. The precision and detail, the development to strict tolerances were all done by people who had studied, trained, tried and tried again to do that work, and do it conscientiously and carefully.

As such, their work was expensive, but justifiably valuable.

Now, with the linking of tools and computers anyone can do it. I applaud the availability of cheap accessible methods for manufacturing whatever you need at home. Gone is the need for a full machine shop, for long apprenticeships and years of labor.

Everyone can design and build almost anything to their hearts content, and the technology and versatility will only get better.

But there’s a darker side.

I used to have a 1967 Thunderbird. The thing was a beast. But open the head, and there was an engine, an alternator and a compressor. Lift the hood, climb on in and go to work.

Now I drive a 99 Explorer. I went to change a spark plug and it turned out I needed three specialized tools.

But it runs on computers! It’s better!

As long as I have $500 to drop whenever I need to do some work.

X-Wing fighter? You’re so low tech.

So here’s my point – making something easier and more accessible is a good thing. It brings prices down. It makes it easier for people to pursue their individual visions.

Here’s the down side is, no one knows how it works. Give me a semi logical Graphical User Interface and I can sort out CAD. I can reconfigure and optimize a Windows computer without too much trouble, and sort out a basic setup on Linux.

But no one knows how it works. Send a dump file to Microsoft and they’ll say “We have no idea what it means”. There’s too much going on and too few people understand it.

So if you have a Makerbot but the platform driver is off 4 millimeters, it won’t print cleanly because the surface isn’t where it should be. And you’ll need high level technical support to sort it.

You can engrave your dowel and do beautifully complex work, but you don’t have the math to sort out what it’s doing or how it should work.

Yes, technology brings a lot of ease and efficiency to our lives. No, no one gets their TVs repaired anymore.

And it seems fewer people know how things work under the hood, and more people rely on them to just do whatever it is they’re supposed to do.

I’m not sure that’s a good thing.

Ok…maybe some technology is a good idea…

(And for anyone interested in a great tale of what technology might be able to do, check out Daemon by Daniel Suarez. Its a great thriller.)